Thanks to a solid experience in the upholstery sector, our team works constantly with the aim of overcoming the limits of traditional production technologies.

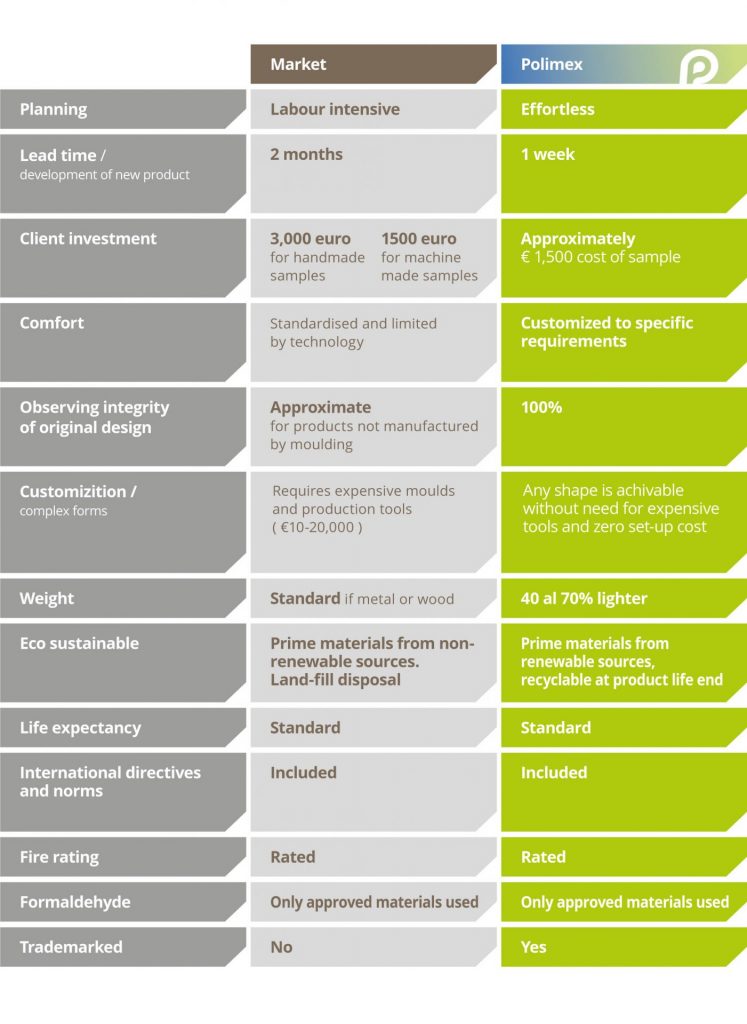

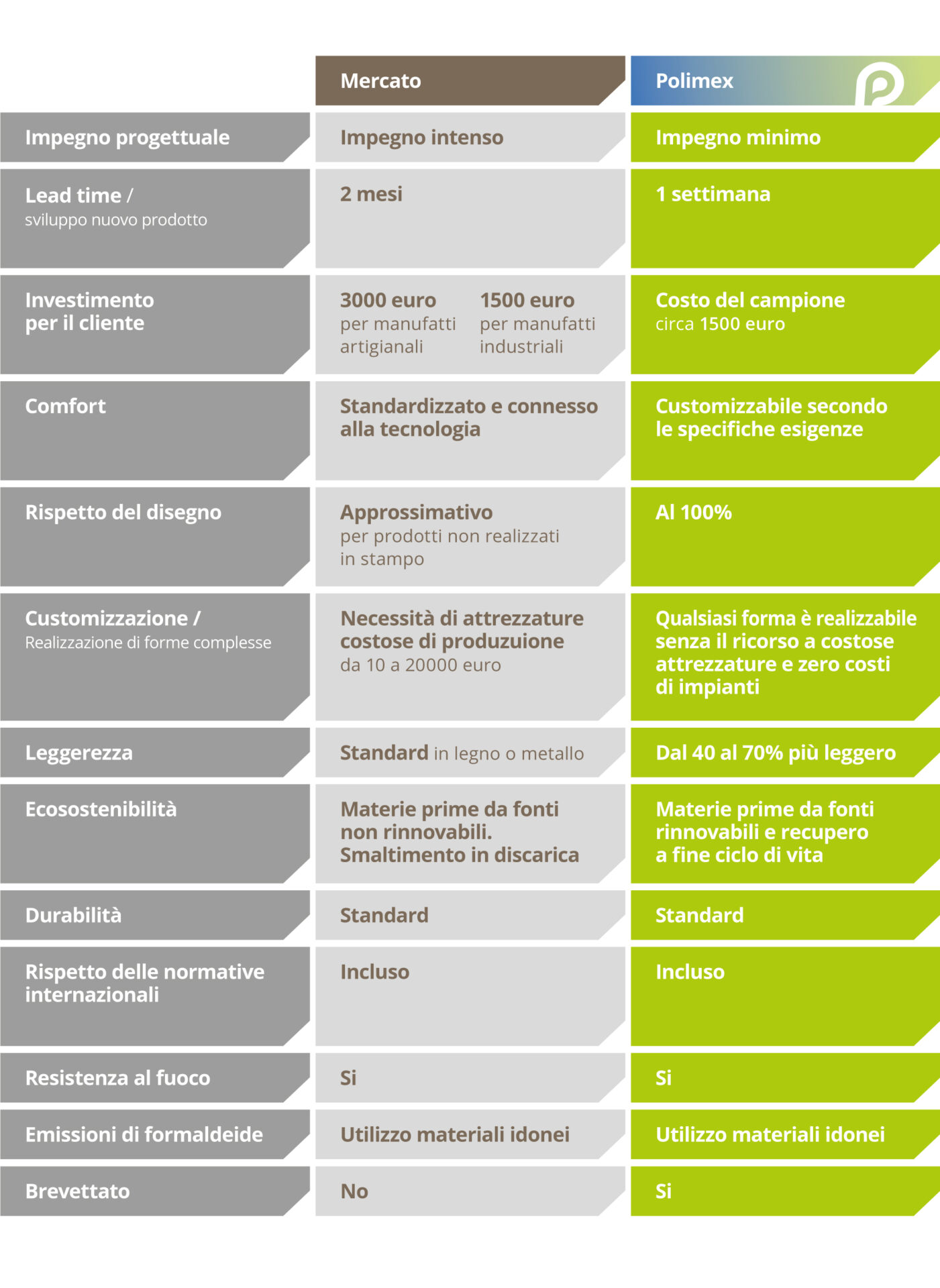

Based on a solid foundation in the upholstery sector, our team is constantly working with the objective of exceeding the limits of traditional production technology. This is what led to the birth of Polimex®: A technological solution trademarked and exclusive to Superevo. Polimex is a composite material ideal for creating load bearing structures for soft furnishings, due to its specific blend of polystyrene and minor percentage of polyurethane (which lends structural integrity). Compared with traditional furnishings, those made with Polimex® are lighter, can take on more complex forms, do not require an initial financial outlay and are sustainable and fast to produce.

Throughout history different materials have been combined to obtain finished products with improved characteristics. In materials science, a composite material is one comprised of multiple different simple materials. Each compound is congruous with a specific phase of the process, so a composite material by nature has a non-homogenous structure; the materials which make up a composite material are separated by a net interface of zero thickness each of which has its own chemical physical properties at a macroscopic and structural level. By sandwich panels (or sandwich structures) we mean an element comprised of two external resistant layers, called the “skin “or “face”, separated by a connective internal material known as the “core”.

POLIMEX® is the name of a patented material made up of various combinations of skin and core. The skins are comprised of various types of polyurethane of elevated mechanical resistance, adapted to the eventual usage of the finished product. The skin contributes to both the flexural and impact resistance.

Varying densities of expanded polystyrene foam are used for the core depending on the required end result; by “foam” we intend the cellular material obtained by the dispersion of a gas into a solid plastic material.

Based on the requirements of the object, foam can be:

- open cell

- closed cell

- flexible, semi-rigid or rigid

- in thermoplastic or thermosetting material

Foam provides excellent thermal and acoustic insulation and has a remarkable capacity for absorbing vibrations and impacts.

Added value

Trademarked in 2008, thanks to its versatility, Polimex®imposes no limits on form or dimension, thus leaving the interpretation of design and creativity in the hands of the Client. Thanks to its structural characteristics it is infinitely lighter than its traditional counterparts.

In addition, the semi-processed material requires a smaller amount of padding or foam to achieve the end product, thus reducing the overall quantity of materials used. Thanks to its composition, the finished product is comprised almost exclusively of Polimex® and the reduction of other components (wood, plastic) facilitates its recycling at the end of its lifespan. We work with internationally certified materials and are able to meet the specific needs of the Client. Polimex® is certified class 1-IM fire resistant thus reducing fire risk.

At Superevo® we chose the road of sustainability quite some time ago, researching various innovative solutions with the objective of continuously improving our green agenda.

This is the reason why we study the life cycle of our products and processes by applying the Life Cycle Assessment methodology, internationally recognized by the ISO 14044-44 standards. Thanks to the LCA we analyse the environmental footprint of our products “from cradle to grave”, meaning from the raw materials to the final disposal at the end of the product’s life. Analysing the strengths and weaknesses throughout the supply chain gives us the possibility to search for innovative solutions and continuous improvements.

Another aspect which we have focused on is how to recycle waste polystyrene. The “first cut” of a semi-processed product will always generate some waste, in our facility this is collected and put into a “bricking” machine, designed to reduce it down and convert it into polyester “bricks”. These bricks are then sold on for the creation of other new products. The objective is to contribute to a circular economy, re-using as much as possible the materials needed to bring a product to life, reworking them and making them suitable for the creation of new products.

Forget about traditional lead times! At Superevo® moulds are considered obsolete, a waste of time and money for the Client. Thanks to the innovation and robotization of the plant, and the optimization of all phases of production, the production to shipping time has been reduced to just a few days. From receipt of the 3D vector model from the Client, our team of technicians and engineers can create a prototype in just 48 hours. Reducing the lead time and avoiding the cost of creating a mould are the key factors which establish a privileged relationship with the Client and define our competitive advantage in the marketplace.

Unleash your creativity. No design is too complicated or too contoured for Polimex®. We have the capability to create any padded form to the exact specifications of the 3D image. Our objective is to work closely with architects, designers and brands who are looking to develop products with unique and complex shapes. Even the search for comfort has now become customizable as the Client has the possibility to choose their own personal comfort level in the various contact zones on the product. Support and softness, density and elasticity are all measured and defined by detailed specifications, even within the same contact zone. The result is unrivalled comfort.

Up to 70% lighter than traditional UPHOLSTERED furnishings; we have always aimed to make our products as lightweight as possible. Structures built with Polimex® are considerably lighter and easier to handle than their metal or wooden counterparts. Increased manoeuverability means easier internal processing at the Clients premises, ease of transportation and easier handling for the end customer. Padded furnishings which are more lightweight but just as resistant as traditional ones. Polimex® products are tested to ensure they maintain shape and integrity over time.